Early days at Watford Electronics

Popular UK hobby magazines like Practical Electronics, Everyday Electronics and Practical Wireless featured a wealth of constructional projects for electronics hobbyists to tackle. Sometimes a local electronics or surplus store held some of the parts in stock, but for most of us, getting components meant sending away for them by mail order. It was often the only way to get some weird or wonderful chip or part needed by a particular project. Hence hobby magazines in those halcyon days were stuffed full of mail order adverts, and trade was very brisk indeed; in fact advertisers were sometimes turned away because the magazine had run out of page space. No chance of that happening today!

One supplier was Watford Electronics Ltd. of Cardiff Road, Watford, a supplier that I myself used in the 1970’s and 1980’s, as I’ve described elsewhere*. So I was delighted to hear from a former staff member at Watford Electronics, Ian Nicholls, who wrote to me with his interesting story describing life behind the scenes in the earliest days of Watford Electronics. I’ve précised it below, for electronics enthusiasts who, like me, used to mail in to Watford Electronics in an era when home computing was also in its ascendency.

* See also:

Earliest beginnings

Ian’s story describes the very earliest days of Watford Electronics Ltd. at their first shop, a converted residential property where business all began, with Raza Jessa selling components from his bedroom there. (Maplin Electronics started in the same sort of way.)

“I was born at Edgware General Hospital and grew up at pre-nursery school in the central London Borough of Islington and Camden. It was an old Victorian school house and solitary life there was a bit miserable in those early years. By around 1969 to 1970 I moved to a new house in Stanmore, Middlesex where new houses cost £10,000, but my parents self-built their own on a plot of land costing £3,000 which was located between some Barratt-built homes.

“I first became aware of electricity when at the age of four, I stuck a metal teaspoon into an MK-brand mains socket Earth (ground) pin, and then bent spoons, forks and knives into the Live socket, turned it on then shot my body across the living room with burnt fingers and hands! I went to a nursery at Honeypot Lane near a strange building which, as far as I know, was a children’s swimming baths in the 1950s. The nursery became Stanmore Library with its curved architecture, shaped like a space ship.

“Later, my mum would run me to primary school on her Honda CB50 scooter or sometimes Dad used his Morris Minor 1000cc Traveller which had with wooden doors on the back. My mum was a legal secretary in Edgeware and my dad was a CNC metal worker in Wembley. The industrial road went around all of Wembley Stadium, where the single road about six miles long had glasshouses that held tropical ferns and trees, which have all long gone. We got a lot of funny looks when my mum brought beds, TVs, furniture, the fridge, gas cooker, all balanced on her Honda CB walking it back on the bike from shops. Fortunately the Edgeware police turned a blind eye!

“I joined the 3rd Stanmore Scout group, which met in an old building behind Stanmore Fire station. The Scout group roof was made of asbestos and had electric heater fans inside - I still have photos of the Scout group at the building in Old Kent Close, long since gone. The Old Kent road address in Stanmore was a ‘close’ not a road, where Bejam frozen foods (which became Iceland – AW) was founded, and beyond that, fed by a separate road from Honeypot Lane, was Marconi where they made radios but mainly Dansette record players which were built, tested and sold from there.

“At Cubs every few months we delivered jumble-sale leaflets door to door to support the Scout group and mum became the sponsor and head of the board and handled the bookkeeping. During our auto jumble or general jumble sales, I got the first look-in with my older brother, and saw the old toasters, kettles, hairdryers, radios and televisions like Philips, Mullard and Marconi televisions which we paid 10-50 pence each for. Dad took them home for us to take apart and maybe get working, while mum was in her element amongst all the used curtains and dresses, as she was a part-time dressmaker too.

“This was the first time I discovered real electric shocks – EHT when old TVs were switched on and working. My brother collected valves (vacuum tubes), and I started to build and play with radio and TV parts: nothing worked but I loved pulling things to pieces.”

Next came secondary school:

“I started Secondary/ High School after my brother left. He knew the school as Chandos High or Chandos Boarding School in Thistlecroft Gardens, Stanmore. [Perhaps https://www.facebook.com/groups/8928339789/ - AW]. It became Park High School.

“My school friends included Robert, David and later Anthony – as I recall David was into sci-fi and James Bond and electronics so he became my best friend. As friends, we went to each other’s houses for lunches, dinners, play and sleep-overs.

“The first electronics thing I built? My friend David flashed a PP3 9V battery across the secondary of a mains transformer with me holding the primary side tightly! I got a shock and I became fascinated by this over many years. I also started working a part-time local milk round from Kenton Farms and I walked everywhere.

“During the first two years of school, I built an electric shock machine out of a 12V mains transformer, a telephone dial, another mains transformer and an old radio box; I took it to school, plugged it in and got everyone to hold hands while I ‘dialled’ 9 on the phone dial and everyone got a 480V shock nine times! I got a three week suspension after the teacher walked in and I was ordered to dismantle it. [At my own secondary school, a pal built a shock machine that he connected to the school bus chassis, and everyone got a belt when they touched the seat frames! – AW]

“With David’s help I soon learned about Volts, Ohm’s Law, Kirchoff’s Law and we worked on a VHS VCR together. In the 3rd year at school this is when ‘life’ started to happen. I started to get engineering magazines about cars from my brother. He wanted to be a car mechanic, at the time when articles on electronics intrigued me, so I bought Everyday Electronics magazines from Woolworths in Queensburys and Martins Newsagents in Honeypot Lane near the library.

“I can’t remember what electronic projects I built, but I had an Old Holburn tobacco tin with leds, battery, capacitor and resistors in the tin held together with sellotape. My dad would take me to Tandy’s Burnt Oak store. For Christmas and birthdays I got wired-control cars, a metal detector, Realistic branded stuff. My sister was into Elvis and wanted a Dansette Tempo. My reading was not good but I was interested in circuit diagrams, and then I saw a magazine advert for mail order electronic components sold Watford Electronics (WE).

“My Dad then got himself a Ford Cortina Mk1 estate car, a big grey thing, and he drove me to the Watford Electronics shop in Cardiff Road so I could get some electronic parts. By now (mid-late 70s), David had me fault-finding video cassette recorders. I started to use my Raleigh bike once a month or so to cycle six miles uphill to Watford, mainly to Tandy Burnt Oak as it was on the flat level.

“Watford Electronics did have a catalogue but I wasn’t interested in it. I had the first few Maplin and ElectroValue typed paper catalogues. By then I’d started to buy all the electronic magazines from WHSmith’s in Queensburys. I recall it was Brian Clipstone from the Scouts group who tried teaching me to design circuit boards from copper-clad boards but he wanted to use copper-strip board, which was not my thing. I wasn’t showing that much interest at the time, the same with diagnosing VCRs, as I just enjoyed playing on my bike, cycling to different places on my own.

“I built and tested a simple car alarm and installed it into my brother’s Lotus Elan 2. Later he got a Triumph Dolomite Sprint while my first car was a Hillman Imp, followed by Ford Cortinas. I rebuilt an engine and gearbox on my own, learning car mechanics and welding from my brother, and I can rebuild an old car myself now.

“From 16-18 I got full time work at a garden centre. After a spell hospitalised, I developed valuable life skills during the best two years in my life. Electronics took off: I made and played musical instruments, learnt woodworking, plumbing, art, photography, and more besides, while coming to terms with some other issues.

“After being at the garden centre, my best friend David offered me a job at Datasound Electronics, part of GEC, as a trainee test engineer to test circuit boards using hexadecimal code. The job folded after six months but I learnt about thyristors, triacs etc which helped me to understand more about electronics.”

Starting work at Watford Electronics…

“In the local paper a job was advertised for Watford Electronics who wanted a store man - ‘part-time, pay negotiable on experience. Please call Watford 40588’, so I thought I’d go up there on my cycle.

“I got there and went in through the front door at Cardiff Road and there was Raza Jessa. He’d served me before, so I asked about the job. Just then a guy called Mohammed Jessa came out to the shop front and said there’s no job before disappearing from view again. Raza said very quietly that yes, there is a job and I’ll be employing you. I said ‘Great!’ then Raza asked for my CV. I said I don’t have it, so Raza said I could come back anytime if still interested. I remember how I’d bought red leds from him. I cycled home and told my mum.

“After a week or two, on the spur of the moment I cycled to WE and spoke to Michael behind the counter. He was the technician for Shiraz Jessa, another family member, and knew me from my shopping trips. He said Raza was not in, but led me in to sit down between the shop and back room. There was a narrow wooden desk and chair, so I sat and waited. I knew Mohammed would sit there as he did the paperwork there. Ten minutes later Raza came in from the front, full of smiles, greeted the customers and staff then came behind the counter to where I was sitting. I got up but Raza told me to sit there so I handed him my CV and Raza asked about my life, experiences, electronics etc. I asked if he owned this business and Raza said ‘Yes’. He’d started in the upstairs front single bedroom above, selling electronic components from his bedroom on his own. After talking, Raza said he’d look at my CV later, but if he employed me then he will be my boss. I said ‘OK’, we shook hands and I left.

“It seemed like weeks went by but within a week Raza phoned my mum. He wanted to see me and mum on a certain day and time, so mum told me, then went out and bought me a suit for the interview. Mum cleaned me up like I’m sparkling. We went there in dad’s car and parked outside shop, as there were no yellow lines anywhere. We walked in and waited with customers queuing to the counter and asked for Raza. He came out straight away and led us up to Mohammed’s desk between the shop and back room. Mum sat and Raza pulled up a chair, talking ages to my mum before telling me it’s part-time work with minimum wage of £2.50 per hour. I was excited! Raza said the job is only three months working in the store room. Start that coming Monday at 9 a.m. Raza then showed us politely to the door.

“On Monday at 9 a.m. Raza opened the shop door saying he’s the only keyholder. Raza had customers in straight away. He said customers come first, so he told me to sit at Mohammed’s desk. So I’m just sat there when Mohammed walked in and told me to get out of his chair. I explained that Raza had told me to sit here and that I introduced myself: ‘I’m Ian and I’ve started work here.’ Mohammed said ‘No, you don’t work here’, and he tried to ‘shush’ me out the shop. Raza stepped in and told Mohammed, who was not pleased at all. Mohammed went out through the back, leaving me standing by the chair for what must be an hour. Raza finished with customers and smiled and showed me about.”

Life at the Watford Electronics shop

The original Watford Electronics shop at 33 Cardiff Road, Watford [click to see]“The shop on Cardiff Road had a metal and half-frosted glass front door with a step up as you entered. Raza had the Yale keys. I recall the large blue and white square vinyl floor tiles. On the right was brown perf-board and the front window displayed electronic components tied directly to the board with wire. As customers approached the shop window they saw lots of components. On the immediate left on brown perforated board were computer parts and cover of manuals like the Sinclair ZX80, Macintosh and parts etc. though no BBC micros at that time. A long glass counter was 10-12 feet away and there was a flip-up and over entry for staff. There was just enough room for staff to squeeze by each other whilst serving customers.

The original Watford Electronics shop at 33 Cardiff Road, Watford [click to see]“The shop on Cardiff Road had a metal and half-frosted glass front door with a step up as you entered. Raza had the Yale keys. I recall the large blue and white square vinyl floor tiles. On the right was brown perf-board and the front window displayed electronic components tied directly to the board with wire. As customers approached the shop window they saw lots of components. On the immediate left on brown perforated board were computer parts and cover of manuals like the Sinclair ZX80, Macintosh and parts etc. though no BBC micros at that time. A long glass counter was 10-12 feet away and there was a flip-up and over entry for staff. There was just enough room for staff to squeeze by each other whilst serving customers.

Thanks to Google Street View we can now browse a decade’s worth of street scenery where we see how the original crazy-paved shop window (see 1978 catalogue) was still there in 2008 before being removed in 2009 onwards. Funny how full-page magazine adverts made suppliers look big. See https://goo.gl/maps/iDrjE8NpfNn In the latest Street View photos, if you zoom out an aerial view is adopted and outbuildings in the back yard can be seen - AW.

“Over on the right was a doorway leading to the middle of the house, and near the back board there were Mitsubishi 5” floppy, both 40 track and 80 track, and later unformatted floppy discs, while below were 3½” inch white discs for the Apple Macintosh. In the middle room were three or four 6’ high turnstiles with four sides full of plastic drawers holding components, each with hand-written labels on the front – about 360 drawers per turnstile.

“The blue/white vinyl walkway went through to a breeze-block dividing wall and a doorway to the back room where Mohammed sat at his wooden desk. Straight into the back room on the immediate left was a large wood table where Geraldine the packer was stationed, helped by Donna and Kelly (or Kerry) helping pack boxes for customers shipped via TNT and a lot by Royal Mail. They were young secretaries who used typewriters at the back of the packing room. A side door led to the back garage outside.

“Customer packages were collected by van, by going down the side entrance and pick-ups were daily or twice daily, jam-packed full into a Royal Mail 7 Ton box lorry. There could be 3,000 parcels per load every day, sometimes twice a day, all packed by Geraldine. The lorry would reverse up to the garage with only 2-3” inches to spare and had to be reversed perfectly straight as it was a long passageway. Most of the men driving would not attempt it, and only one driver – a woman named Rachael would do it – and she helped us out many times later too, voluntarily.

“There was also an old panelled dark green door leading to the store room. As soon as you entered it you went down 18 steep wooden steps to the basement under the shop floor joists. As the height from floor to joist was 5’ 6” I, being 6’ tall, had to bend and crouch around the storeroom. The stairs back up again were only 2’ 6” wide so you could very easily fall and seriously hurt yourself. You could hear customers walking in and out the shop above, but no-one knew I was working underneath where customers walked!

Packing BBC Micro EEPROMs

“In the back corner directly under the front door of the shop, I would sit with my coffee, weigh scales and something that Raza had made: a 12V metal box with wire between two binding posts that glowed red hot! I used to cut the plastic tubes for EEPROMs this way, then sellotaped the ends and packed white boxes with a programmed DFS chip [Disk Filing System for the BBC Micro*]. We had rolls of Watford Electronics DFS stickers that I put onto EEPROMs before packing the chip in a tube and packing it with a manual, disk and a white WE leaflet.

* See http://www.computinghistory.org.uk/det/34533/Watford-Electronics-DFS/

“I must have done tens of thousands for BBC Model A, Model B, Model B Plus and the BBC Master. I think there were around 24 different EEPROMs besides the store room holding bandoliers of 100,000 resistors of each value, counting chips, transistors, etc. The place was lit by 60W bulbs and there was no ventilation, so in summer I sat there sweating buckets, hearing the floor above creak and the stairs creak too. Later Raza had to put in steel braces to hold storeroom joists up, as the wooden 8” joists were bending under the weight and the concrete on the walls was crumbling with me working underneath!

“In the back room were some 3’ 6” wide stairs with a handrail up to the first floor. I would go up there to the kitchen to have lunch. You constantly had to barge past people coming down, usually the two or three technicians. Our technicians were Nick, Michael and Shiraz Jessa, who headed the technical dept. I did not get along with Shiraz at all.

“The landing upstairs was small, with red patterned carpet all around. The former front bedrooms where it all started had desks where technicians answered tech calls, repaired and designed things. The small back bedroom was used for computer storage. I used to eat my fish & chips up there for an hour’s lunch break. Raza would pop up between seeing customers to chat and get a drink.

“Arif came on the scene every now and again. He was cheerful and used to finish school and come down to the shop, while Mohammed was mainly out of the country and I hardly ever saw him. In my opinion Raza was the best one I worked for. I had lots and lots of happy memories with them, and best of all they were Muslims and treated the staff with care and compassion. Raza called me his brother and sometimes he’d would come down after business meetings, take off his jacket and tie and help me carry dirty boxes up the stairs. Raza was the only boss that would help me like this, but Watford Electronics was his business at that time.

“Outside the property there was an up-and-over double garage where we actually stored computers, printers and drives, EEPROM erasers, dot matrix printers including the best selling Epson EF80 and Zenith green or orange-screen monitors. You could open a single-glaze cast iron window and look out the back at the grass lawn next door at No. 35 Cardiff Road, and get told by Raza to keep off the grass! No. 35 led most of its life unfurnished and the house was never used.”

Next came the move to a new, purpose built site – 250 Lower High Street, Watford.

Watford Electronics moves onwards and upwards

Jessa House, 250 Lower High Street, Watford [click to see] © GoogleAs expansion beckoned Watford Electronics, Ian gives an insight into the move to a new location - Jessa House.

Jessa House, 250 Lower High Street, Watford [click to see] © GoogleAs expansion beckoned Watford Electronics, Ian gives an insight into the move to a new location - Jessa House.

I found the location on Google Maps here: https://goo.gl/maps/i7J6HKPbxTM2 © Google 2009

“I was a store man for three months, after which I accepted a full time position there. After another six months they were already building a new site to expand the business at 250 Lower High Street, Watford. This state-of-the-art building had all purpose-built fittings. I had to supervise the move from 33 Cardiff Road to the new building. A 250,000 square feet warehouse on Water Pump Lane (up the road from Watford Tech College) was also used for storing AT/ XT computers as well as TINY computers, which kept business flowing for years after the shop at Cardiff Road closed down.

“I supervised the move from 33 Cardiff Road to the brand new site, called Jessa House. It was a lovely bright red brick building and they’d negotiated a favourable rate with Watford Council. It had non-slip beige laminated floors and solid dark brown doors inside. I saw them installing high-speed Internet and phone lines every 10ft or so with power into the floor, and aerial sockets downstairs and one floor above.

“However I wasn’t allowed to go up the ‘front’ stairwell to see what’s up there, but I understood it was intended for Nazir Jessa. I thought it was a purpose-built flat and maybe office, and I’ve been told it had all the mod-cons with lavish trimmings and a rooftop terrace. There was a private entrance from the front car park, and it had skylights (atrium) that can be seen on Google Street View. There was a separate ‘back’ stairwell to the first floor.

“The windows of 250 Lower High Street on the ground level and first floor were top spec. No-one could see into the building from outside. The glass filtered out UV and helped maintain the constant temperature in winter or hot summer. Everyone got hardwood tables and desks, comfy swivel chairs and special ‘daylight’ lighting to reduce eye strain and help with color correction. The downstairs offices had wool carpets and curtains with blinds. Upstairs, the first floor was open warehouse with lots of rows of shelves. To the back of the building was a covered entrance over the back door, and there was a fully built kitchen.

“The back of the building had a gravel staff car park and the Goods In entrance. Staff had to use this back entrance where a clocking-in machine had been installed. The only people allowed to use the front entrance and access through the shop were the Jessa family. Compared to its heyday, the building now looks in a sorry state. Various steel shutters have been put in or windows bricked up since then.

“The move to the new site went well. Everything was transported by their old Ford Transit 3.5 ton van. Different Jessa family members drove the van with me riding along as a loader. Raza was the only one who took off his jacket and helped me carry dirty boxes up the back stairs though.

“I think the first day of trading was 1st August or September and at 9 a.m. the press and a television crew filmed the big day. As customers entered they were greeted by Raza or Shiraz and Mohammed went too, along with the technical team Nick and Michael. They were shown around the walls to the glass counter, just like it was at Cardiff Road with a screen behind the counter, then up to six turnstiles of components. I think on its first day the Jessas claimed over £200,000 of takings. After we’d moved to Jessa House, within the first year the Jessa family treated all of us to a two week fully inclusive holiday to Paris as a thank you.

“In the building itself, in the open space next to the turnstiles I stacked BBC computers and laser printers as well as the famous FX80 and LX80 Epson printers. I shipped in the XT/ AT and other TINY computers from our external warehouse. Meantime Tesco started to build a superstore opposite us and they diverted the river!

Mopping up the TI 8271 for the BBC Micro A and B

“The BBC Micro A and B computers had a Texas Instruments 8271 CPU that sometimes overheated and at one stage the UK ran out of those chips. Dixons shop in the town centre sold the chip for £50 but when UK ran out they charged £250 for each chip. So Raza with Mohammed visited TI and snapped up the entire UK stock to reserve for their special customers, charging just £25 each chip. When the chip was so hard to come by, the UK price went through the roof, but we had thousands of them safe in storage on the first floor, which I looked after myself. Throughout all the time at Watford Electronics, Geraldine ran the packing dept. on her own, from Cardiff Road to Jessa House and I believe also Finway House in Luton [the second and final expansion] before finally retiring.

“I started at Watford College to learn Electronics City and Guilds, a three year course which I passed with Distinction. Geraldine had her 10th year working for Watford Electronics and was awarded with a 22ct. watch and a two week fully paid Caribbean holiday for her family.

“I learned that the entire Jessa family were Muslims who originally came from Tanzania. Raza always defended me over the years and was the best one to work for in my experience. Three times a day I would hear from the downstairs toilet front stairwell, chanting and singing! I noticed that they all prayed at different times facing Mecca and they all attended Hendon Mosque. There were often (foreign-language) phone calls being made and even satellite video-calling before the days of the Internet back then. The Jessa family supported local mosques and always helped out local charities each year.

“While rival computer suppliers were struggling, Watford Electronics went from strength to strength. The firm floated on the Stock Exchange as a blue-chip company. I was told at a staff meeting that Watford Electronics had made a bid to buy Microsoft in its entirety as well as Texas Instruments itself, for £240 million. These deals fell through which caused the share price to plummet. I did not hear anything after that.

“A few years on, Nazir became the director of WE and Raza gave up complete control. Various projects fell through along the way. Watford Electronics went into liquidation about one year before the shop closed. Although customers thought that things were going great, there was extreme financial tension behind the scenes.

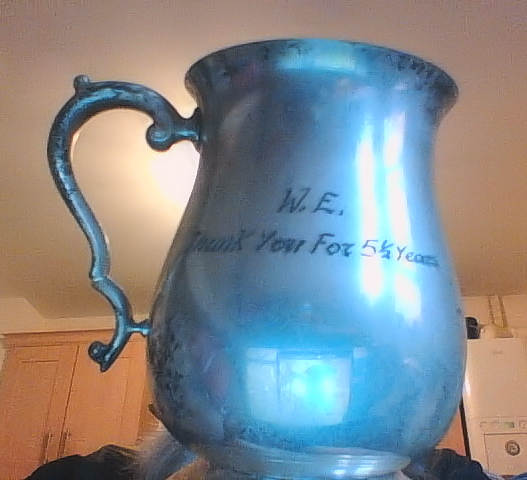

5½ years of service with Watford Electronics, with my engraved tankard“When SUPERSAVE came into existence, I left the firm after 5½ years. I was asked what I wanted as a leaving present: I said a tankard saying ‘Thank you for 5½ years at Watford Electronics.’ – which is exactly what I was presented with.”

5½ years of service with Watford Electronics, with my engraved tankard“When SUPERSAVE came into existence, I left the firm after 5½ years. I was asked what I wanted as a leaving present: I said a tankard saying ‘Thank you for 5½ years at Watford Electronics.’ – which is exactly what I was presented with.”

Ian Nicholls

See also my other links:

- http://alanwinstanley.squarespace.com/hobby-electronics/2018/7/15/the-legacy-of-watford-electronics-ltd.html

- http://alanwinstanley.squarespace.com/alan-winstanleys-journal/2017/7/7/saverstorecom-lights-out.html

Thursday, October 27, 2022 at 9:58PM

Thursday, October 27, 2022 at 9:58PM

Reader Comments (3)

I was a primary school governor in the 80s and 90s. Sarah Jessa attended the school and was popular with the staff and pupils. She was a good football player and the boys always wanted her on their team. She subsequently went to Watford Girls' Grammar School and I guess that her football playing stopped.

Back in the 70's I was selling electronic components, (wholesale), from a couple of major franchised distributors. I sold CMOS and General Instruments chips to Nazir and Raza, including Pong and Tank.

Many a time we went out for meals together and I even got to visit Nazir's new house.

I remember Nazir telling me that in his years as an optician up to and including the early days of Watford Electronics he never discarded packaging and as a result never had to buy any supplies for the mail order side of the business for the first few years of operation.

I also helped them out at trade shows because I was programming early home computers (Ohio Scientific) that they were selling, (and yes, I bought my first one from them)

Great memories!

I worked there 97'ish great place to be. However the introduction talk was the weirdest that I have every had. Basically the talk went on the lines: Jezza family great, you never will be as great don't even think about repeating this success. You should be thankful you will work for us....

Anywho I literally walked out after it was pretty clear that what I was promised at the job interview was not going to happen.

I assume this is the Ian I remember who had red hair and really along with Razza were the hands on people.